What Are the Advantages and Applications of 7mm Seamless Panels?

1. Visual Revolution at 7mm: Precision Manufacturing for Flawless Surfaces

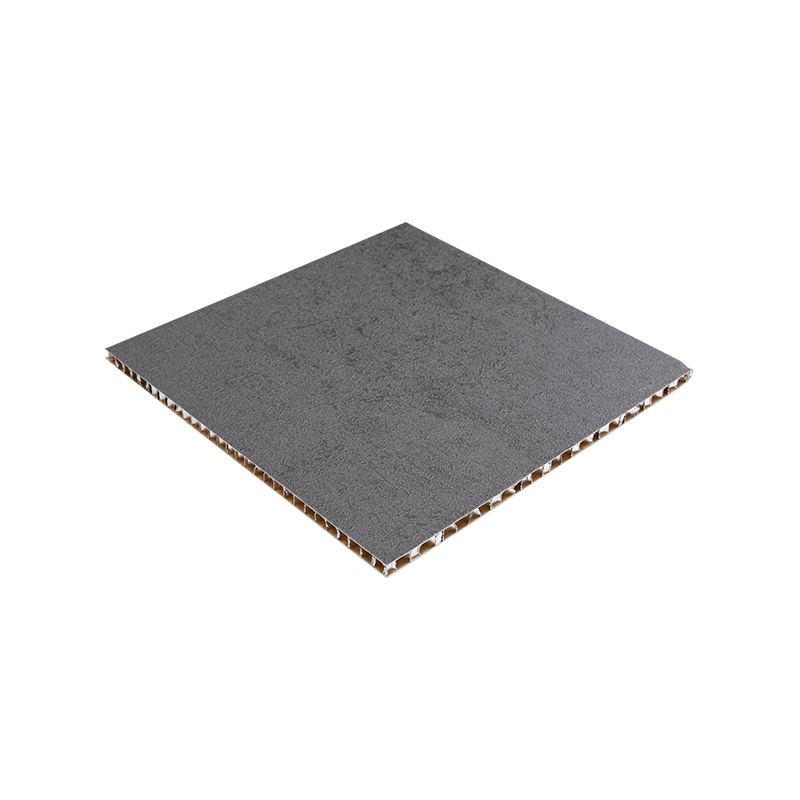

The pursuit of a perfectly smooth, monolithic appearance in modern interiors is made possible by 7mm Seamless Panels. This ultra-thin profile belies the sophisticated engineering required to achieve seamless visual continuity. For a manufacturer like Zhejiang QianDuoMu Intelligent Decoration Co., Ltd., specializing in ceiling and wall systems, the “seamless” quality is not just an aesthetic claim but the result of precision manufacturing, controlled material behavior, and integrated installation systems. The goal is to create expansive surfaces where the individual panels visually disappear, leaving only the intended design.

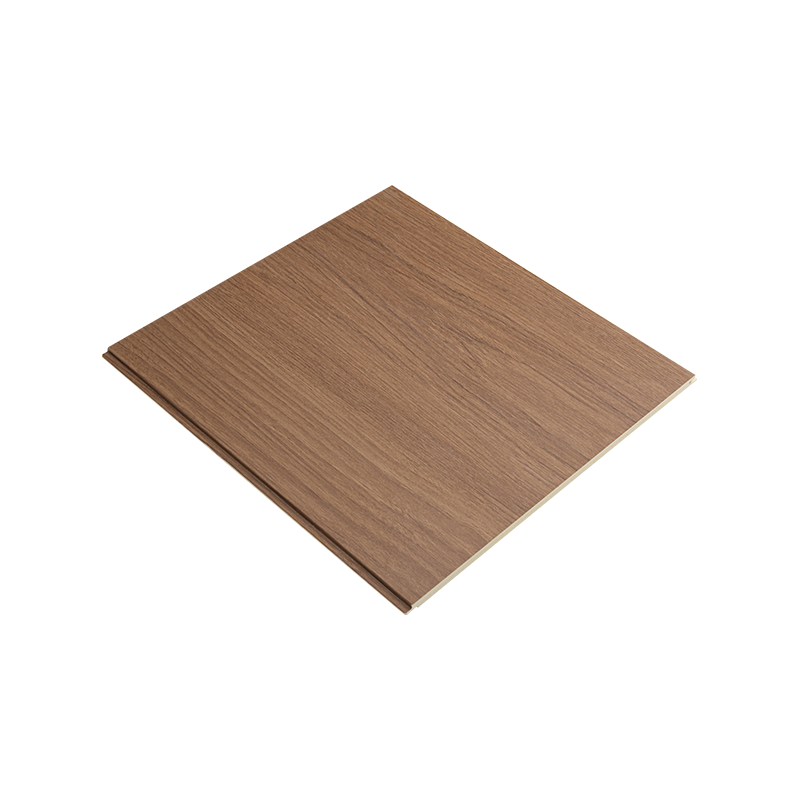

- Flatness and Edge Precision: Achieving a seamless look starts with exceptional panel flatness, typically measured to within strict tolerances (e.g., < 0.5mm per meter). The edges of each panel are machined with high accuracy to ensure straightness and perfect right angles, which is critical for tight, consistent joint lines.

- Joint Design and Concealment: Special edge profiles, such as tongue-and-groove or stepped designs, allow panels to interlock precisely. When combined with specialized installation clips and, in some cases, minimal applied sealants, the joint becomes virtually invisible from a standard viewing distance.

- The Role of Automated Production: Modern, automated lines ensure dimensional consistency across thousands of panels, which is the foundational requirement for a successful large-scale seamless installation. This repeatability is a key advantage of working with an established producer.

2. Performance Beyond Aesthetics: Fire Safety and Acoustics

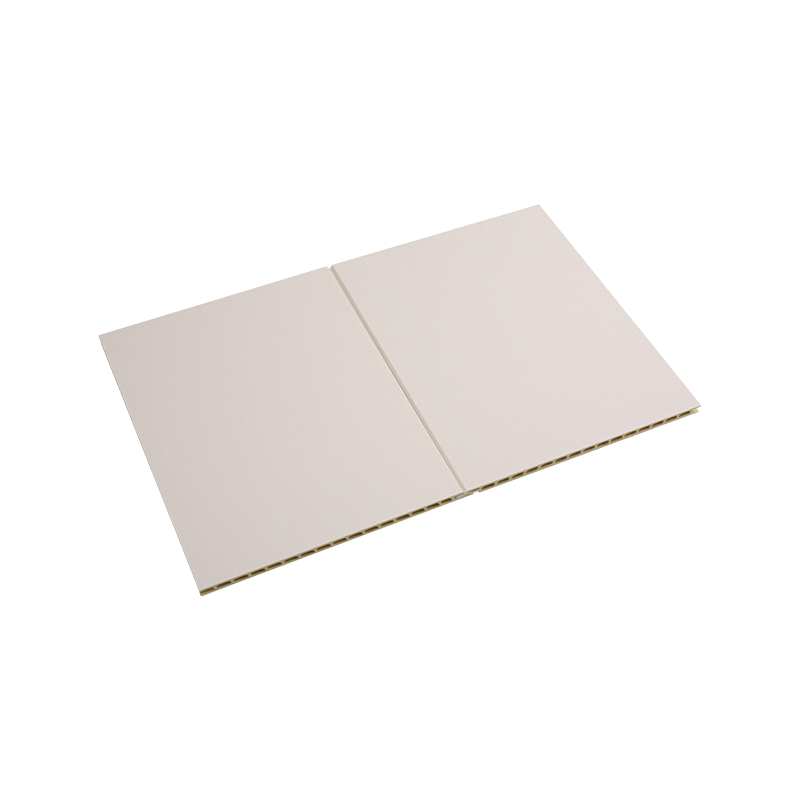

A premium interior panel must deliver more than just good looks. The 7mm aluminum honeycomb ceiling panel seamless construction is inherently performance-oriented, offering critical benefits that comply with stringent building codes for commercial and public spaces.

Engineered for Safety and Comfort

- Inherent Fire Rating: The core material—aluminum—is non-combustible. When paired with mineral-based or other fire-retardant cores in a honeycomb sandwich structure, these panels can consistently achieve high fire safety classifications, such as Class A or its international equivalents. This makes them a reliable choice for projects where fire rated materials are mandatory.

- Acoustic Dampening Properties: The honeycomb core structure acts as a natural damper for sound waves. By specifying panels with perforated aluminum faces and adding sound-absorbing fleece or foam behind them, the system can provide significant Noise Reduction Coefficient (NRC) values, contributing to quieter, more comfortable interior environments.

Comparison of Core Benefits

| Performance Aspect | How 7mm Seamless Aluminum Honeycomb Panel Delivers |

| Structural Rigidity | The honeycomb core provides high strength-to-weight ratio, preventing sagging or warping over large spans despite the thin profile. |

| Thermal Stability | Aluminum's properties minimize expansion/contraction, maintaining joint integrity across temperature fluctuations. |

| Lightweight Nature | Significantly lighter than solid materials, reducing load on building structures and simplifying handling during retrofit ceiling installation. |

3. Large-Scale Customization for Commercial Spaces

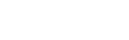

The demand for branded, unique interiors has made customization a standard requirement. The ability to produce large size seamless aluminum panel for wall cladding and ceilings in custom colors, textures, and dimensions is what separates basic suppliers from true project partners.

- Custom Color and Finish Matching: Advanced powder coating or PVDF (Polyvinylidene Fluoride) coating lines allow for precise color matching to any RAL or Pantone standard. This is essential for custom color schemes in corporate offices, retail stores, or hospitality venues where brand identity is paramount.

- Handling Large Panel Sizes: Supplying oversized panels reduces the number of joints on a wall or ceiling, enhancing the seamless effect. This requires sophisticated logistics, from handling in the factory to secure packaging and transport, capabilities inherent to a manufacturer with a large-scale production base.

- Integrated Solution Provision: For complex projects, service extends beyond manufacturing to include technical support for detailing junctions, providing specialized fixing systems, and guidance on installation best practices to realize the designed vision.

4. The Ideal Choice for Renovation and Retrofit Projects

Modernizing existing buildings presents unique challenges, making the properties of the 7mm seamless panel particularly advantageous. Its combination of low weight, high strength, and clean aesthetics solves multiple retrofit problems simultaneously.

- Minimizing Structural Load: The lightweight nature of aluminum honeycomb panels adds minimal dead load to existing ceiling structures. This is a critical safety and feasibility consideration in renovations, often avoiding the need for costly structural reinforcement.

- Fast, Dry Installation: Many seamless panel systems are designed for dry installation using concealed clips or rails. This creates less dust and disruption than wet trades (like plastering), allowing businesses to remain operational with shorter downtime during ceiling upgrades.

- Concealing Existing Imperfections: A new, rigid panel system can be installed over an old, damaged, or uneven ceiling, creating a perfect new surface without the mess and time required for demolition and repair of the original substrate.

5. Global Standards: Quality Control for International Projects

Supplying materials for international contracts requires a commitment to quality that transcends borders. A manufacturer's dedication to standardized processes is key to ensuring that every panel, whether for a project in the United Kingdom or Australia, meets the same high standard.

- Certifications as a Foundation: Holding recognized management system certifications (like ISO 9001 for quality) demonstrates a company's commitment to process control. This forms the backbone of reliable production.

- Comprehensive Testing Regime: Product quality is verified through rigorous in-house testing for parameters such as coating adhesion, hardness, color fastness, and panel flatness. This data provides objective assurance to specifiers and contractors.

- Consistency Across Batches: For large or multi-phase projects, maintaining absolute consistency in color, finish, and dimensions from the first shipment to the last is non-negotiable. Automated production and strict raw material sourcing are essential to achieve this.

FAQ

Can 7mm seamless panels really be used on large ceilings without visible sagging?

Yes, when designed and installed correctly. The key is the aluminum honeycomb core. This structure is exceptionally rigid for its weight, providing high resistance to bending. The panels must be supported by an appropriate grid system at specified spans, as recommended by the manufacturer. For very large areas, the use of heavier-gauge aluminum faces or a slightly thicker panel (while still maintaining the seamless aesthetic) might be specified by an engineer to guarantee long-term flatness.

How are the joints between these panels finished to be "seamless"?

The "seamless" look is achieved through a combination of precision and technique:

- Tight Mechanical Joints: Panels have machined edges that fit together tightly, often with a recessed or shadow-line profile that minimizes the visual impact of the gap.

- Professional Installation: Using a trained crew with the correct leveled grid system is crucial. Panels are snapped or clipped into place under tension to ensure alignment.

- Final Treatment: In some systems, a fine, color-matched filler or sealant is applied into the joint and smoothed flush. For others, the dry joint design itself is so precise that no filler is needed, which is preferred to avoid potential cracking over time.

Are these panels suitable for humid environments like bathrooms or swimming pools?

Aluminum is inherently rust-proof and resistant to moisture. For high-humidity environments, it is critical to specify panels with a suitable protective coating. A high-quality PVDF coating offers excellent resistance to humidity, UV rays, and chemical exposure, making it the preferred choice for swimming pool ceilings, spa areas, or exterior soffits. Always confirm the specific coating's suitability and warranties for the intended environment with the manufacturer.

What is the lead time for custom-colored or oversized panels?

Lead times vary but are generally longer than for standard stock items. For custom color panels, factor in time for color matching approval and the setup of the coating line. For large size or non-standard dimensions, additional time for tooling setup or specialized handling may be required. A professional manufacturer will provide a realistic timeline based on project complexity and current production schedule. For large projects, phased deliveries are often planned to align with the construction timeline.

English

English عربى

عربى русский

русский