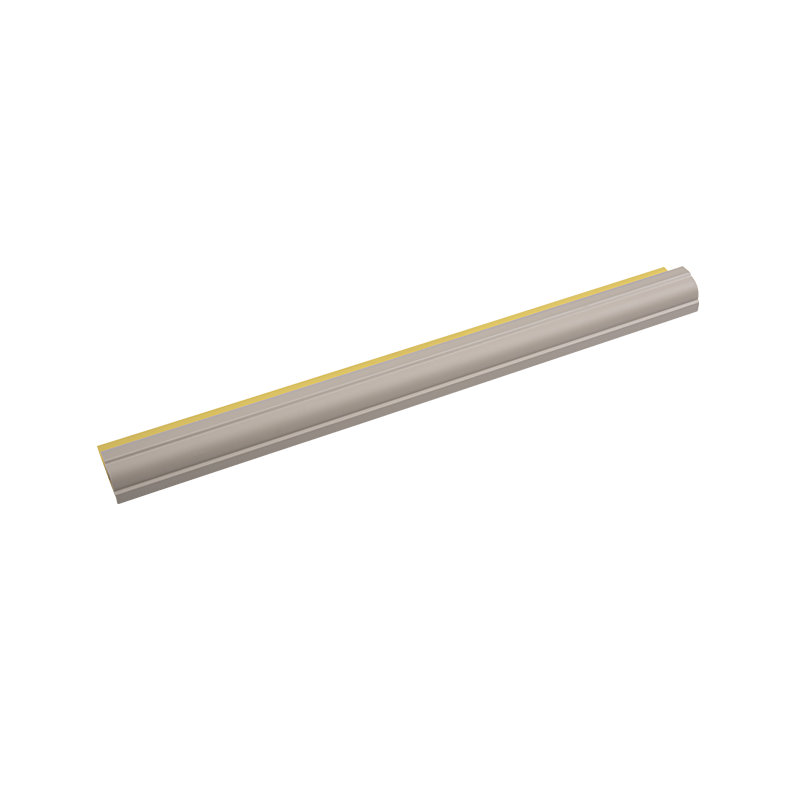

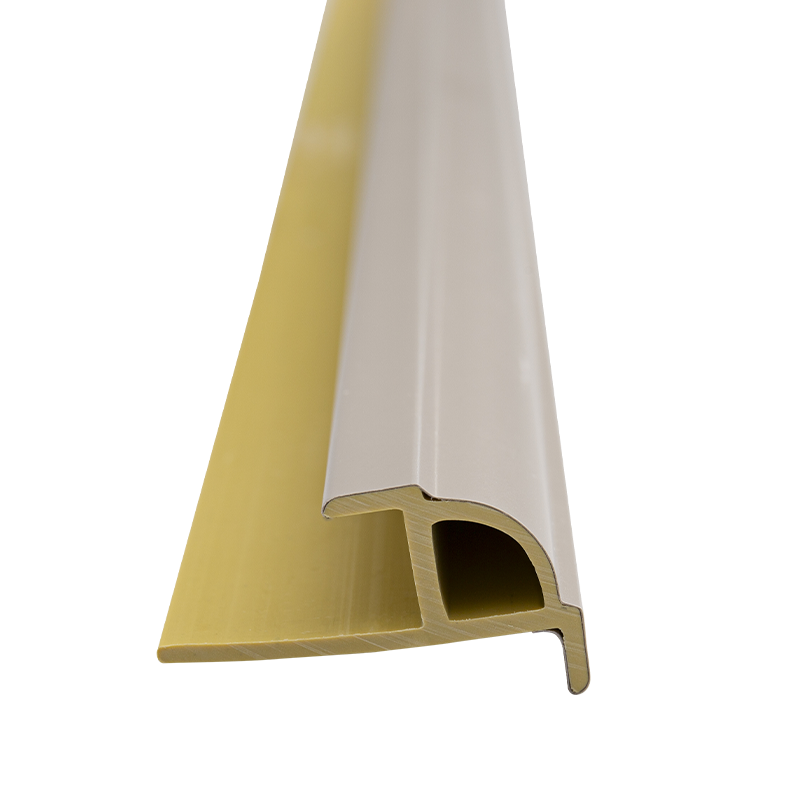

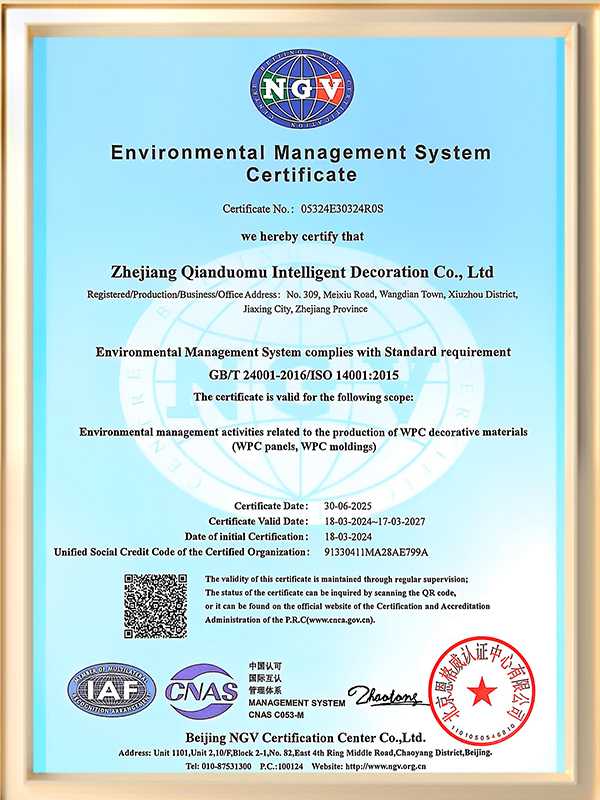

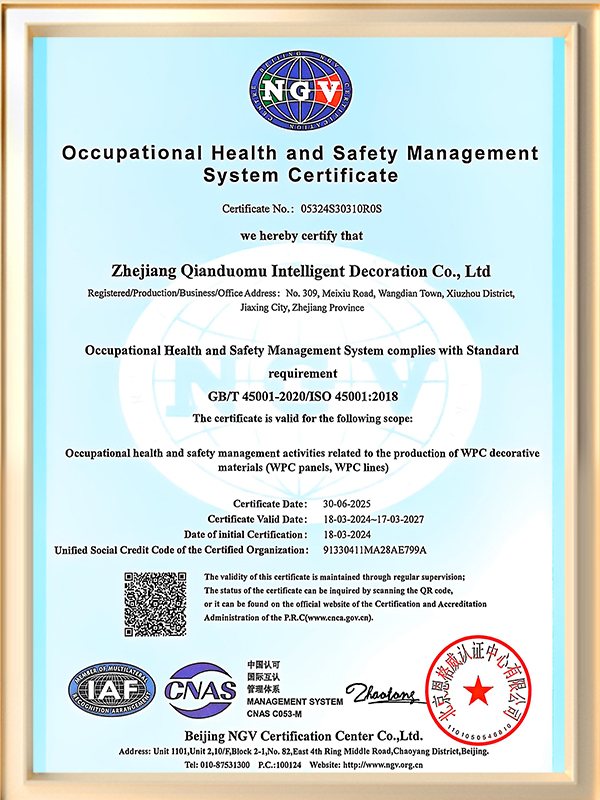

External corner moldings are made from a wood-plastic composite material (WPC) made from wood powder, calcium powder, and polymer materials. The moldings are crafted using a standardized process. Their core design focuses on "rounded shape + practical protection." They are specially designed for decorative and protective wall corners, resolving the issues of traditional right-angled corners, which are prone to scratches and difficult to maintain.

The key selling points are clear: the WPC base is inherently mildew- and moisture-resistant, resisting mold and deformation even from daily cleaning splashes and humidity fluctuations, maintaining its integrity over time. The rounded shape, lacking sharp edges, effectively protects the elderly and children from accidental injuries, making it particularly suitable for spaces requiring protective equipment. The surface can be customized in multiple colors, adapting to styles such as modern minimalism, new Chinese style, and light luxury, complementing the color palette of the walls and wall panels without disrupting the overall quality of the decor. The material is also highly durable and scratch-resistant, resisting damage to the corners from furniture movement and daily friction, reducing maintenance hassles. The snap-on installation is convenient and requires no complex procedures.

·Home decoration: External corners in living rooms, bedrooms, entryways, and children's rooms.

·Industrial equipment: hotel guest room external corners, clothing store wall external corners, office building corridor external corners, training institution classroom external corners, etc.

English

English عربى

عربى русский

русский