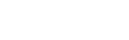

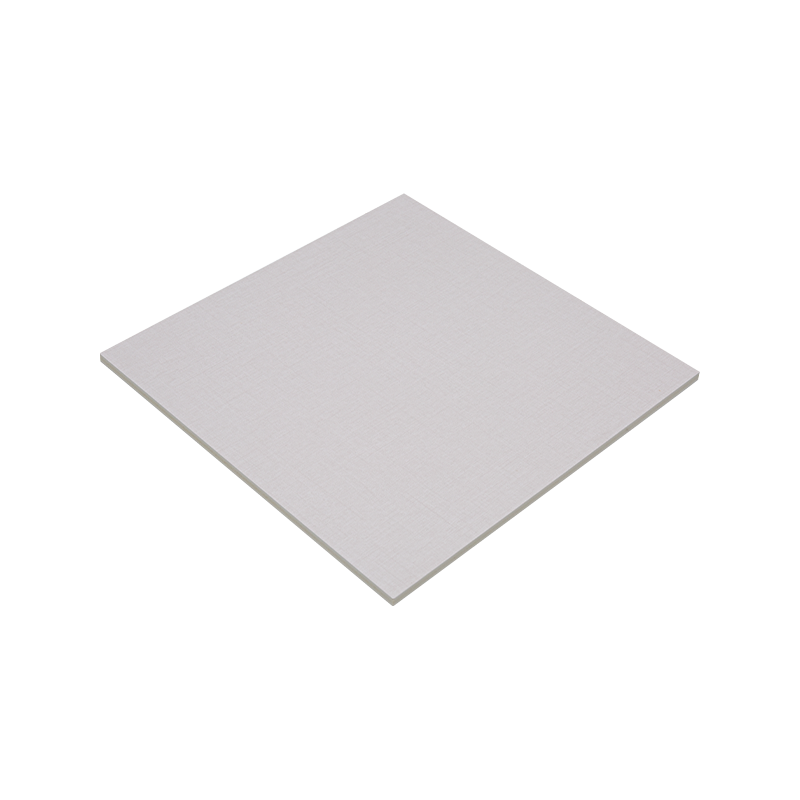

Co-extruded board is a new type of composite board manufactured using a multi-layer co-extrusion process. It uses calcium powder, wood powder, and polymer materials as its base material. Dedicated co-extrusion equipment fuses the different functional material layers together in a single process. This innovative process allows the board's various layers to complement each other, preserving the stability of the base material while imparting diverse functional properties.

This delivers the multiple advantages of structural reinforcement, waterproofing, moisture resistance, easy cleaning, and durability, demonstrating excellent overall performance in a variety of applications.

·Strong Structure: The multi-layer composite structure significantly enhances the board's overall strength, providing strong impact resistance, resistance to cracking and deformation, and the ability to withstand heavy loads.

·Waterproof and Moisture-Resistant: The high-density molecular structure creates a natural barrier that resists water absorption. Even with prolonged exposure to water or humidity, it will not swell or mold, far exceeding the moisture resistance of traditional wood or paper boards.

·Easy Cleaning and Durable: The smooth, dense surface resists dust and stains, requiring only a damp cloth for daily cleaning. It also offers a certain degree of chemical resistance and withstands common cleaning agents, ensuring low maintenance costs.

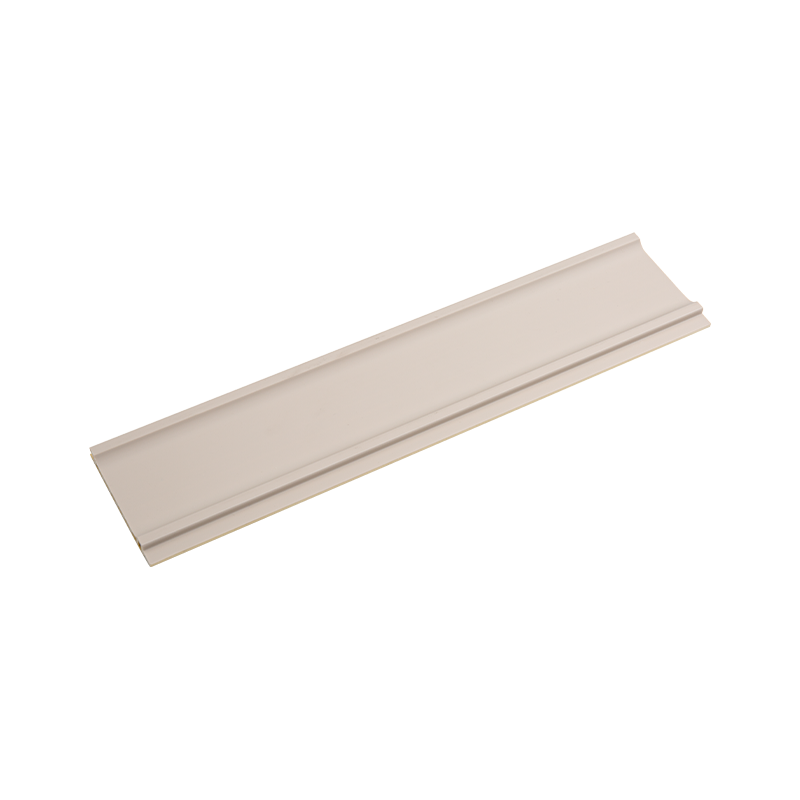

·Home furnishings: Corridors, living and dining rooms, entryways, furniture edges, etc.

·Industrial decoration: Hotel corridors, hospital wards, shopping malls, restaurants, etc.

English

English عربى

عربى русский

русский