In the world of modern architecture and interior design, the quest for materials that combine aesthetic appeal with functional resilience is never-ending. Among the frontrunners in this category are Mirror Aluminium Composite Panels. These innovative building materials are revolutionizing facades, interiors, and signage by offering the pristine, reflective elegance of glass with the unparalleled strength, lightness, and versatility of aluminum composite material (ACM). This article delves deep into the specifics of mirror-finish ACPs, exploring their composition, benefits, applications, and key considerations for selection and installation. We will also address some of the most common and pressing questions professionals have about this dynamic material.

What Are Mirror Aluminium Composite Panels? Composition and Manufacturing

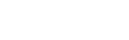

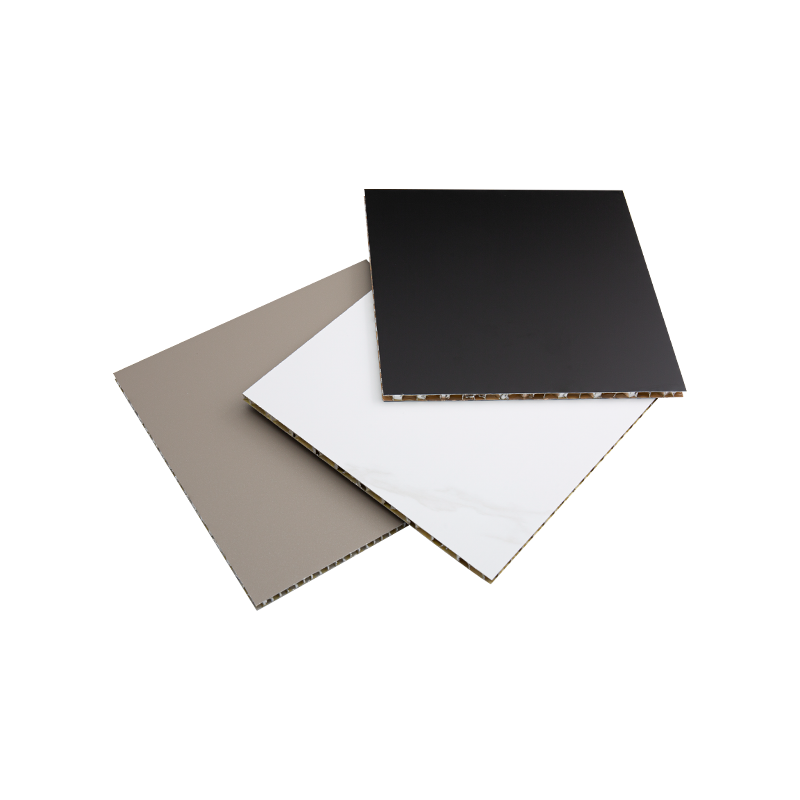

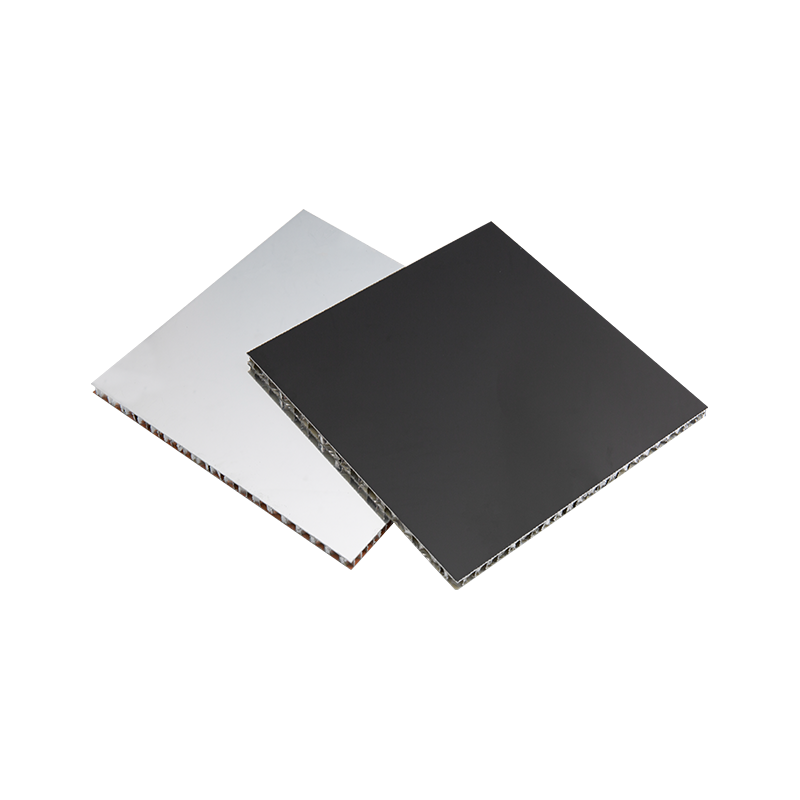

To truly appreciate the value of mirror aluminium composite panels, one must first understand their sophisticated structure. Unlike a simple sheet of polished metal, these panels are engineered laminates designed for optimal performance. The standard construction consists of three core layers: two sturdy aluminium sheets bonded to both sides of a thermoplastic core, typically made from polyethylene (PE) or a fire-retardant mineral-filled core (often referred to as FR). The mirror effect is achieved through a specialized coating process applied to the outer aluminium surface. This process often involves advanced techniques like Physical Vapor Deposition (PVD) or high-gloss PVDF (Polyvinylidene Fluoride) painting, which create a highly reflective, mirror-like finish that is remarkably durable and resistant to tarnishing, corrosion, and UV rays. The result is a panel that is not only stunningly reflective but also lightweight, flat, and easy to fabricate and install compared to solid glass or metal mirrors.

- Layered Structure: The sandwich design provides exceptional rigidity and flatness while minimizing weight, preventing the warping or distortion common in thin, solid metal sheets.

- Coating Technology: The high-tech mirror coating is integral to the panel's durability. PVD coatings, for instance, create a hard, ceramic-like layer that is highly resistant to scratches, chemicals, and fading.

- Core Options: The choice of core material (PE vs. FR) directly impacts the panel's fire rating and suitability for different building types and height restrictions, a critical consideration in commercial projects.

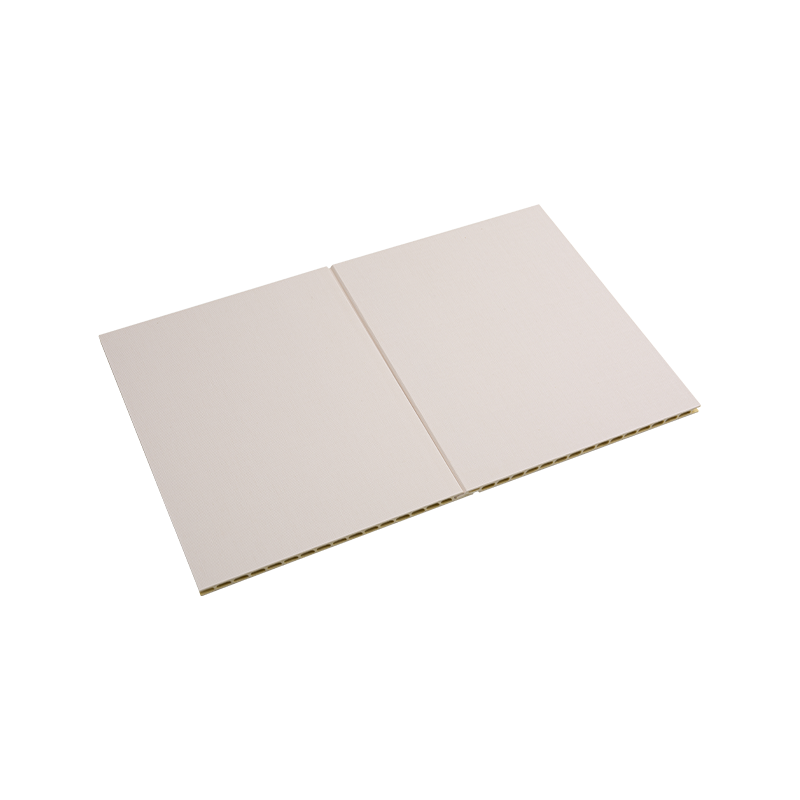

- Customization: Beyond the standard silver mirror finish, panels can be produced in tinted mirrors (e.g., gold, bronze, blue) and with varying levels of reflectivity, from high-gloss to semi-mirror effects.

Key Advantages of Choosing Mirror ACPs

The decision to specify mirror ACP cladding is driven by a compelling array of advantages that address both design aspirations and practical project requirements. From an architectural perspective, these panels create dramatic visual effects, making spaces appear larger, brighter, and more open by reflecting light and surroundings. They can be used to blend structures into their environment or create striking, iconic landmarks that stand out. From a builder's and owner's perspective, the benefits are equally significant. The lightweight nature of ACPs reduces the load on the building's structural framework, potentially leading to cost savings in support systems. Their durability translates to lower long-term maintenance costs, as they resist weathering, pollution, and graffiti. Furthermore, their prefabricated nature allows for fast, efficient installation, shortening project timelines.

- Enhanced Aesthetics & Spatial Perception: Creates illusion of depth and expansiveness, ideal for small spaces or feature walls.

- Superior Durability & Weather Resistance: Outperforms traditional glass mirrors in outdoor applications due to better impact resistance and resistance to thermal stress.

- Lightweight & Structural Efficiency: Significantly lighter than glass, easing handling, transportation, and structural support needs.

- Ease of Fabrication & Installation: Can be easily cut, bent, drilled, and routed on-site or in the workshop, allowing for complex shapes and seamless installations.

- Low Maintenance & Longevity: The non-porous surface is easy to clean and maintains its reflective shine for years with minimal upkeep.

Diverse Applications in Architecture and Design

The versatility of mirror finish aluminium panels unlocks a vast spectrum of applications across multiple sectors. In commercial architecture, they are a premier choice for building facades and curtain walls, offering a sleek, corporate image while providing functional weather shielding. They are extensively used in interior design for feature walls, column covers, ceilings, and retail displays, adding a touch of luxury and modernity. The signage and branding industry relies on them for creating eye-catching, durable signs and logos. A less obvious but growing application is in specialized environments like clean rooms, laboratories, and hospitality venues, where their hygienic, easy-to-clean surface and reflective properties are highly valued. For instance, understanding the specific requirements for mirror ACP for interior walls versus exterior facades is crucial for optimal performance.

- Building Facades & Exterior Cladding: Creates dynamic, reflective skins that change appearance with the sky and surroundings.

- Interior Feature Walls & Ceilings: Used in lobbies, hotels, restaurants, and retail stores to create focal points and enhance ambient light.

- Commercial Signage & Branding Elements: Provides a premium, durable base for corporate logos and directional signs.

- Column Wraps & Decorative Elements: Transforms structural columns and beams into design features.

- Specialized Applications: Suitable for areas requiring high hygiene or specific reflective properties, such as medical facilities or photometric rooms.

Mirror ACP vs. Traditional Glass Mirrors and Stainless Steel

When considering a reflective material for a project, architects and designers often weigh mirror aluminium composite panels against traditional alternatives like silvered glass mirrors and polished stainless steel. A detailed comparison reveals why ACPs are frequently the superior choice for many contemporary applications. Glass mirrors offer perfect reflectivity but are heavy, fragile, difficult to install in large formats, and pose safety risks upon breakage. Polished stainless steel provides a metallic sheen and is very durable, but it is heavier than ACP, can show fingerprints and scratches easily, and often requires more expensive fabrication. Mirror ACPs strike an exceptional balance, offering high reflectivity, extreme lightness, impressive durability, and unparalleled ease of installation and customization. The following table outlines the key differences.

| Feature | Mirror Aluminium Composite Panel (ACP) | Traditional Glass Mirror | Polished Stainless Steel |

| Weight | Very Light | Very Heavy | Heavy |

| Impact Resistance | High | Very Low (Fragile) | High |

| Safety | Safe, no shattering | Hazardous if broken | Safe |

| Installation Ease | Easy (Light, can be cut on-site) | Difficult (Heavy, fragile) | Moderate (Heavy, requires skilled fabrication) |

| Maintenance | Easy to clean, resistant to tarnish | Easy to clean, but edges can degrade | Requires frequent polishing to prevent fingerprints/scratches |

| Cost (Material & Installation) | Moderate | Low (material) to High (installation/safety) | High |

Essential Considerations for Specification and Installation

Successfully integrating mirror ACP sheets into a project requires careful attention to specification details and installation protocols. One of the first decisions involves the choice of core material—standard polyethylene (PE) or fire-retardant (FR) core—which must comply with local building codes and the project's safety requirements. The thickness of the panel (e.g., 3mm, 4mm) and the quality of the mirror coating (PVDF vs. PVD) will affect durability, flatness, and cost. For exterior applications, the panel system's ability to handle thermal expansion, drainage, and wind loads is paramount. This is where details like the joint design, backing system, and recommended installation for mirror aluminium composite panels come into play. Proper installation by certified professionals using appropriate brackets and sealants is non-negotiable to ensure long-term performance, prevent water ingress, and maintain the flawless reflective appearance.

- Fire Rating Compliance: Always verify the core material's fire classification (e.g., A2, B1) against national and local building regulations, especially for high-rise or public buildings.

- Panel Gauge and Flatness: Thicker panels (4mm) offer better flatness over large areas. Specify tolerances for bowing or waviness to ensure a perfect mirror effect.

- Coating Quality and Warranty: Opt for coatings with high UV resistance (e.g., 70% PVDF resin) and check the manufacturer's warranty against fading, chalking, and corrosion.

- Substrate and Fixing System: Ensure the supporting structure (substrate) is perfectly flat and stable. Use a compatible, non-staining fixing system (e.g., cassette, rout-and-return) designed for ACP.

- Expansion Joints and Sealants: Design and implement adequate expansion joints to accommodate thermal movement. Use high-quality, neutral-cure silicone sealants that will not stain the mirror surface.

Maintenance and Care for Long-Lasting Brilliance

While mirror aluminium composite material is renowned for its low maintenance, implementing a correct cleaning and care regimen is essential to preserve its aesthetic appeal for decades. The good news is that the process is straightforward. Regular cleaning with mild, non-abrasive agents is sufficient to remove dirt, grime, and pollutants that can accumulate, especially on exterior facades. It is critical to avoid harsh chemicals, abrasive pads, or metal scrapers that can permanently scratch or damage the delicate mirror coating. For general cleaning, a solution of mild soap or detergent with lukewarm water, applied with a soft cloth, sponge, or squeegee, is ideal. Rinse thoroughly with clean water to prevent streaking. For tougher stains like graffiti, specific solvents recommended by the panel manufacturer should be used after testing in an inconspicuous area.

- Recommended Cleaning Frequency: For exterior facades, a bi-annual or annual cleaning schedule is typically adequate. Interiors may require more frequent dusting and occasional cleaning.

- Safe Cleaning Agents: Use pH-neutral soaps, detergents, or cleaners specifically formulated for coated aluminium or glass. Avoid acidic (vinegar) or alkaline (bleach) cleaners.

- Proper Tools: Use soft, non-abrasive cloths (microfiber), sponges, or soft-bristle brushes. Never use steel wool, scrapers, or abrasive pads.

- Rinsing is Key: Always rinse the panel thoroughly with plenty of clean water after washing to remove all soap residue, which can cause streaks and attract more dirt.

- Inspection Regimen: As part of routine building maintenance, periodically inspect the fixings, sealants, and panel surfaces for any signs of damage, staining, or sealant failure.

FAQ

Are mirror aluminium composite panels suitable for outdoor use?

Yes, mirror aluminium composite panels are highly suitable for outdoor applications, making them an excellent choice for mirror ACP cladding on building exteriors, facades, and signage. Their durability stems from the robust aluminium sheets and the advanced protective coatings (like PVDF or PVD) that are specifically engineered to withstand harsh environmental conditions. These coatings provide exceptional resistance to UV radiation, preventing the mirror finish from fading, chalking, or yellowing over time. They also offer high corrosion resistance against rain, pollution, and salt spray (in coastal areas). Furthermore, the thermoplastic core and the panel's composite structure allow it to handle thermal expansion and contraction better than solid materials, reducing the risk of warping. However, for optimal longevity, it is crucial to specify panels with an appropriate fire-retardant core if required by code, ensure a high-quality coating system, and follow precise installation guidelines that include proper drainage and joint detailing.

How do mirror ACPs compare in cost to glass mirrors for a large facade project?

When evaluating the cost for a large-scale facade project, mirror finish aluminium panels often present a more favorable overall value proposition compared to traditional glass mirrors, despite potentially having a higher initial material cost per square meter. The total installed cost of glass mirrors escalates significantly due to several factors: their extreme weight requires heavier and more expensive structural support systems, they are fragile and risk breaking during transport and installation (leading to waste and replacement costs), and their installation is slower, more complex, and demands specialized labor and equipment due to safety concerns. In contrast, mirror ACP sheets are lightweight, reducing structural support costs. They are robust, reducing breakage waste. They can be fabricated and installed quickly using standard metalworking tools and techniques, lowering labor costs. Additionally, their long-term durability and lower maintenance needs contribute to a better lifecycle cost. Therefore, while the sticker price of the ACP material might be comparable or slightly higher, the total project cost is often lower, and the value in terms of safety, speed, and longevity is greater.

Can mirror ACPs be curved or bent for custom design shapes?

Absolutely. One of the most significant advantages of mirror aluminium composite material is its excellent formability, which makes it ideal for creative and custom architectural designs. Unlike glass, which requires costly and complex thermal bending processes, ACPs can be cold-formed or bent relatively easily in a workshop using standard sheet metal machinery such as brake presses or roll formers. This allows for the creation of curved facades, rounded columns, wave-like features, and other non-linear shapes. However, critical considerations must be taken into account to preserve the mirror finish. The bending radius must adhere to the manufacturer's specifications (usually a minimum radius is specified based on panel thickness) to prevent the coating from cracking or delaminating. The bend should always be made with the mirror coating on the outside of the curve (tension side). For complex double-curvature shapes, specialized forming techniques may be required. Consulting with the panel supplier and an experienced fabricator during the design phase is essential to ensure the desired aesthetic result is achievable without compromising the panel's integrity.

What are the fire safety ratings for mirror ACPs, and how do I choose the right one?

Fire safety is a paramount concern in construction, and the rating of mirror aluminium composite panels depends almost entirely on the material used in their core. There are two primary types: panels with a polyethylene (PE) core and those with a fire-retardant (FR), mineral-filled core. Standard PE core panels are combustible and typically carry lower fire performance ratings; they may be restricted or prohibited in many building codes for use above a certain height or in specific building types (like high-rises, hospitals, schools). Fire-resistant mirror ACP panels with an FR core are designed to meet stringent fire safety standards. The mineral core inhibits flame spread and reduces smoke production, allowing these panels to achieve higher fire classifications such as A2 (non-combustible) or B-s1,d0 (very limited contribution to fire) under European EN standards, or similar Class A ratings under other international codes. To choose the right panel, you must first understand and comply with your local building regulations and the specific requirements of your project (building height, occupancy, proximity to boundaries). Always request and verify the official fire test certification from the panel manufacturer or supplier to ensure compliance.

How do I clean and maintain the mirror finish to prevent scratches and cloudiness?

Maintaining the pristine, reflective surface of your mirror ACP for interior walls or exterior cladding is simple if you follow the correct procedures. The primary rule is to treat the surface gently, as the mirror coating, while durable, can be scratched by abrasives. For routine cleaning, use a soft, clean cloth (microfiber is ideal), sponge, or a soft squeegee. Prepare a cleaning solution with lukewarm water and a small amount of mild, pH-neutral dish soap or a cleaner specifically recommended for coated aluminium or windows. Avoid harsh chemicals, ammonia-based cleaners, abrasive powders, or acidic solutions like vinegar. Apply the solution, gently wipe the surface, and then rinse thoroughly with plenty of clean water to prevent soap residue from drying and causing streaks or a hazy film. For dried-on pollutants or graffiti, use a manufacturer-approved solvent and always test it in an inconspicuous area first. Never use steel wool, scrapers, wire brushes, or abrasive cleaning pads. Establishing a regular, gentle cleaning schedule will prevent the buildup of stubborn dirt and keep your mirror aluminium composite panels looking brilliantly new for years.

English

English عربى

عربى русский

русский