The Foundation: What Defines a True 7mm Seamless Panel?

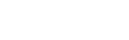

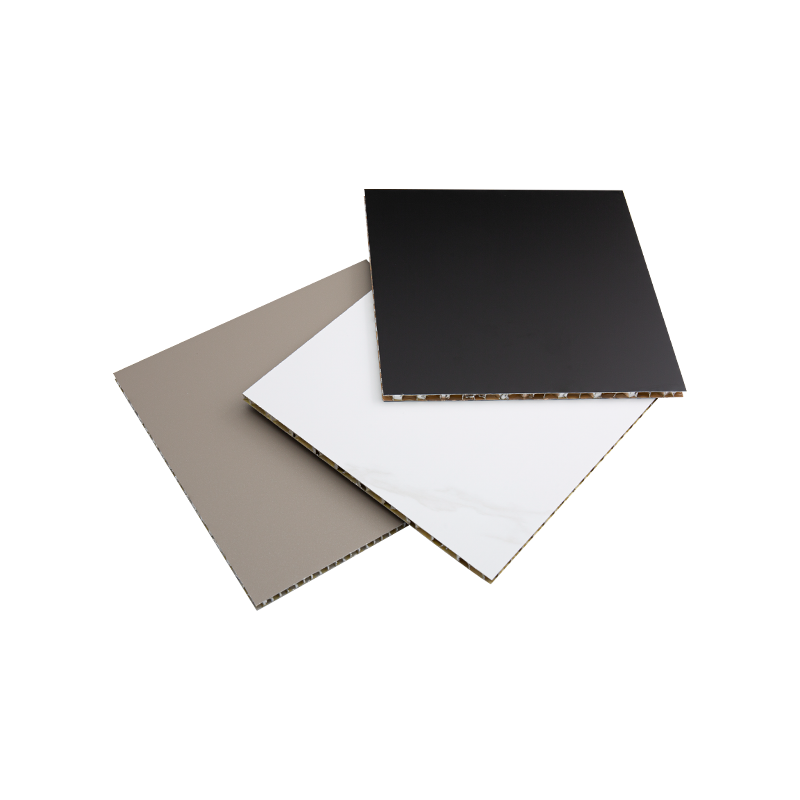

A 7mm seamless panel represents a sophisticated evolution in interior cladding, moving beyond mere decoration to become a high-performance architectural system. The term "seamless" refers not just to a visual effect but to an engineered outcome achieved through precision manufacturing and integrated installation. At its core, the panel's remarkable properties are derived from its sandwich construction: two thin, rigid aluminum face sheets bonded to an aluminum honeycomb core. This structure is the key to achieving a combination of lightness, flatness, and strength that is unattainable with solid materials of comparable thickness. For manufacturers committed to modern production and quality control, this product exemplifies the fusion of material science and design intent, enabling architects to realize expansive, unbroken interior surfaces.

- Aluminum Honeycomb Core: The hexagonal honeycomb structure acts like a continuous beam, distributing loads evenly and providing exceptional rigidity. This prevents sagging and warping, which is critical for maintaining the flat, seamless appearance over large ceiling spans or tall wall sections.

- Precision Edge Machining: The "seamless" visual is born in the factory. Each panel's edges are precision-machined to exact tolerances, allowing them to fit together with a consistent, minimal gap. This meticulous edgework is the first and most crucial step in ensuring the installed system appears as a continuous plane.

- Dimensional Stability: Aluminum has a low coefficient of thermal expansion. Combined with the stable honeycomb core, these panels exhibit minimal dimensional change due to temperature or humidity fluctuations, ensuring that the tight joints and flat surfaces are maintained long-term in varying indoor climates.

Performance Engineered for Code and Comfort

In commercial, institutional, and high-end residential projects, interior materials must perform on multiple fronts: they must comply with strict safety regulations while actively contributing to occupant well-being. The 7mm aluminum honeycomb seamless ceiling panel is engineered to excel in these areas, moving it from a simple finish to a functional component of the building envelope. Its inherent material properties provide a strong foundation for meeting some of the most demanding project specifications.

Meeting Stringent Safety Standards: The Science Behind Fire Rated A Class Performance

For projects in sectors like transportation, healthcare, and public assembly, material fire safety is non-negotiable. A fire rated A class 7mm seamless panel leverages the natural properties of its components to achieve the highest classifications. Aluminum face sheets are non-combustible, and when paired with mineral-based cores or other advanced fire-retardant infills, the entire sandwich assembly can resist flame spread, produce minimal smoke, and contribute little to no combustible fuel load. This performance is not merely claimed but is validated through rigorous standardized testing, providing specifiers and building officials with the certified documentation required for permit approvals and occupant safety.

Beyond the Visual: Acoustics and Thermal Benefits

The performance benefits extend into occupant comfort. The honeycomb core's cellular structure inherently disrupts sound wave transmission, providing a degree of acoustic damping. When specified with perforated aluminum faces and appropriate backing materials, these panels can be engineered into effective acoustic ceilings or wall systems, absorbing ambient noise and reducing reverberation in spaces like open-plan offices, restaurants, or auditoriums. Additionally, the sealed air pockets within the honeycomb core provide improved thermal insulation compared to solid metal panels, contributing to a building's overall energy efficiency and creating a more comfortable surface temperature.

Design Freedom Realized: Aesthetics and Customization

The ultimate value of an interior material lies in its ability to translate a design vision into reality without compromise. Seamless panels offer unprecedented design freedom, moving from standardized offerings to fully customized architectural elements. This capability transforms them from a commodity into a key tool for brand expression and unique spatial design.

Unlocking Brand Identity with Custom Color Matching

The ability to execute a precise color scheme is fundamental to architectural branding. Advanced manufacturers offer true custom color matching 7mm seamless metal panel services, utilizing high-durability coatings like PVDF (Polyvinylidene Fluoride). This process involves creating a custom color formulation to match any RAL, Pantone, or physical sample provided by the design team. The coating is then applied under controlled conditions to ensure color consistency across every panel in the project, regardless of batch or production date. This eliminates the risk of visible color variation on large surfaces, ensuring the finished space reflects the exact design intent.

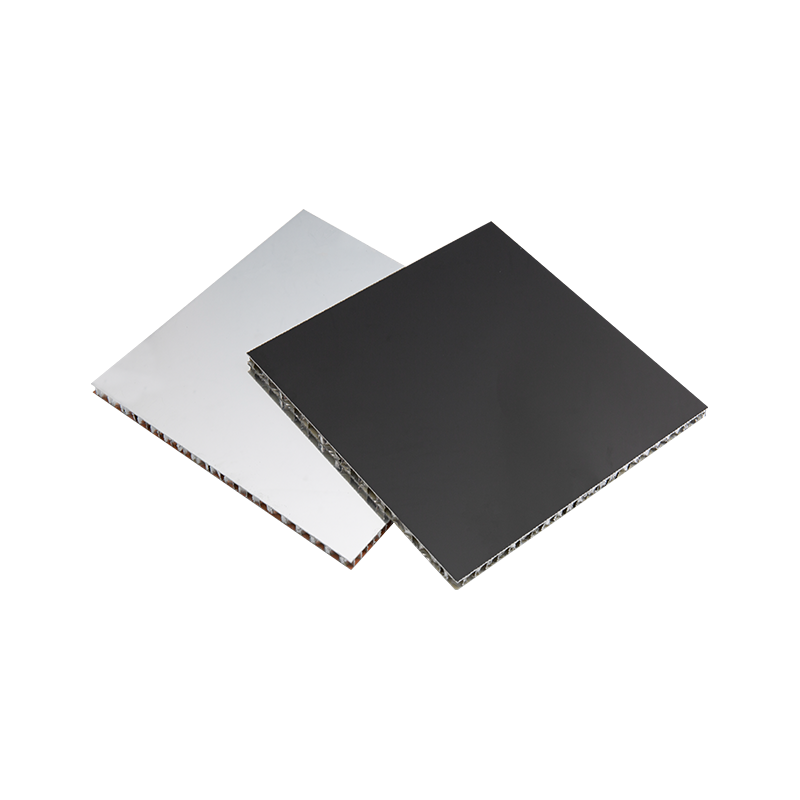

Creating Monumental Spaces with Large Format Wall Panels

The scale of a space has a profound psychological impact. Utilizing large format 7mm seamless wall panels minimizes the number of joints on a critical visual plane, enhancing the sense of scale, grandeur, and simplicity. These oversized panels are particularly effective in corporate lobbies, luxury retail stores, and museum galleries. Supplying and installing such panels requires specialized handling, logistics, and installation expertise to manage their size and weight while protecting their perfect finish, a capability that distinguishes full-system providers from simple material suppliers.

| Design Aspect | Traditional Tiled Panels | Large Format Seamless Panels |

| Visual Impact | Gridded, busy appearance with frequent joint lines. | Clean, monolithic, and expansive; emphasizes space rather than pattern. |

| Design Flexibility | Limited by standard tile sizes and grid alignment. | Enables custom scaling, can be treated as a continuous canvas for integrated lighting or graphics. |

| Perceived Quality | Standard, commercial-grade feel. | Conveys luxury, precision, and high-end architectural intent. |

The Installation Edge: Ensuring Success from Plan to Completion

The most beautifully manufactured panel is only as good as its installation. A successful large format 7mm seamless wall panel installation requires meticulous planning, the correct supporting system, and skilled tradespeople. The inherent advantages of the panel system, particularly its lightweight nature, also open doors to specific and challenging project types, such as renovations.

Best Practices for Flawless Installation

Professional installation begins long before the first panel is lifted into place. It requires a perfectly prepared substrate or a precisely leveled and aligned metal grid system. Panels are typically attached using concealed mechanical clips that allow for thermal movement and precise height adjustment. The precise machining of the panel edges allows them to interlock cleanly. For the ultimate seamless finish, joints can be treated with a color-matched, high-performance sealant that is tooled flush, rendering them invisible from a standard viewing distance.

The Ideal Solution for Modernization

Renovating existing buildings often presents constraints that new construction does not, such as limited structural capacity or the need to minimize disruption. This is where the benefits of a lightweight 7mm panel for renovation projects become decisively advantageous. Their minimal weight places negligible additional load on existing building structures, often eliminating the need for costly and time-consuming structural reinforcement. Furthermore, many seamless systems are designed for dry, mechanical installation over existing ceilings or problematic walls, enabling fast-track upgrades with less dust, debris, and business interruption compared to traditional demolition and wet trades.

Making the Informed Choice: Specification and Sourcing Guide

Selecting the right supplier for a seamless panel system is a critical project decision. It involves evaluating more than just price per square meter; it requires assessing technical capability, quality assurance, and project support. A partner should demonstrate a command of the entire process, from material science to on-site problem-solving.

- Key Questions for Your Supplier: Inquire about their in-house testing capabilities for fire ratings and mechanical performance. Ask for details on their coating process and guarantees for color consistency and durability. Request case studies or references from projects of similar scope and ambition.

- Understanding Certifications and Samples: Always request and verify copies of relevant product certifications (fire, emissions, etc.). Before placing a full order, obtain physical production samples—not just small swatches—to approve the finish, color, and edge detail. A reputable supplier will facilitate this and provide full technical data sheets.

- Project Partnership: The best suppliers act as consultants. They should be willing to review installation drawings, provide detailed technical submittals for architect and contractor approval, and offer support throughout the installation process to ensure the design vision is perfectly executed.

FAQ

Can 7mm seamless panels be used in high-humidity areas like bathrooms or swimming pools?

Yes, they are an excellent choice for such environments, provided the correct specifications are met. Aluminum is inherently corrosion-resistant. The critical factor is the protective coating. For areas with constant high humidity or direct exposure to chlorinated atmospheres (e.g., indoor pools), a high-performance PVDF coating is mandatory. PVDF offers superior resistance to moisture, chemicals, and UV degradation compared to standard polyester coatings. Always confirm with the manufacturer that the specific panel system, including its core material and any seals, is rated for the intended environment.

What is the typical maximum span for a 7mm seamless ceiling without visible sagging?

The allowable span depends on several factors: the specific grade and thickness of the aluminum faces, the density of the honeycomb core, the panel width, and the type of support grid used. As a general rule, a well-engineered 7mm aluminum honeycomb seamless ceiling panel can typically span 1.2 to 1.5 meters between supports without issue. For larger spans or specific load requirements (like supporting integrated light fixtures), manufacturers perform engineering calculations and may recommend a modified design, such as a slightly thicker face sheet or additional mid-span support. Always consult the manufacturer's technical data for span tables specific to their product.

How does the long-term cost of a seamless system compare to a traditional suspended ceiling?

While the initial material and installation cost for a seamless system is typically higher, a long-term value analysis often reveals advantages. Traditional tile ceilings require periodic cleaning, panel replacement due to damage or staining, and can look dated over time. A high-quality seamless system, with its durable coating and robust construction, offers exceptional longevity with minimal maintenance. Its timeless aesthetic also adds enduring value to the property, potentially offering a better return on investment over the lifespan of the building interior by avoiding costly aesthetic refreshes.

Can lighting, air vents, and sprinklers be integrated into a seamless panel ceiling?

Absolutely. One of the hallmarks of a sophisticated seamless system is its ability to cleanly integrate building services. Custom-cut openings can be fabricated in the factory for recessed LED lights, linear light slots, diffusers for air conditioning, and sprinkler heads. The edges of these cut-outs are typically finished with matching trim or bezels to maintain a cohesive look. This requires close coordination between the panel supplier, the architect, and the MEP (Mechanical, Electrical, Plumbing) engineers during the design phase to ensure all apertures are accurately located and sized on the shop drawings before production begins.

English

English عربى

عربى русский

русский