Introduction

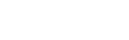

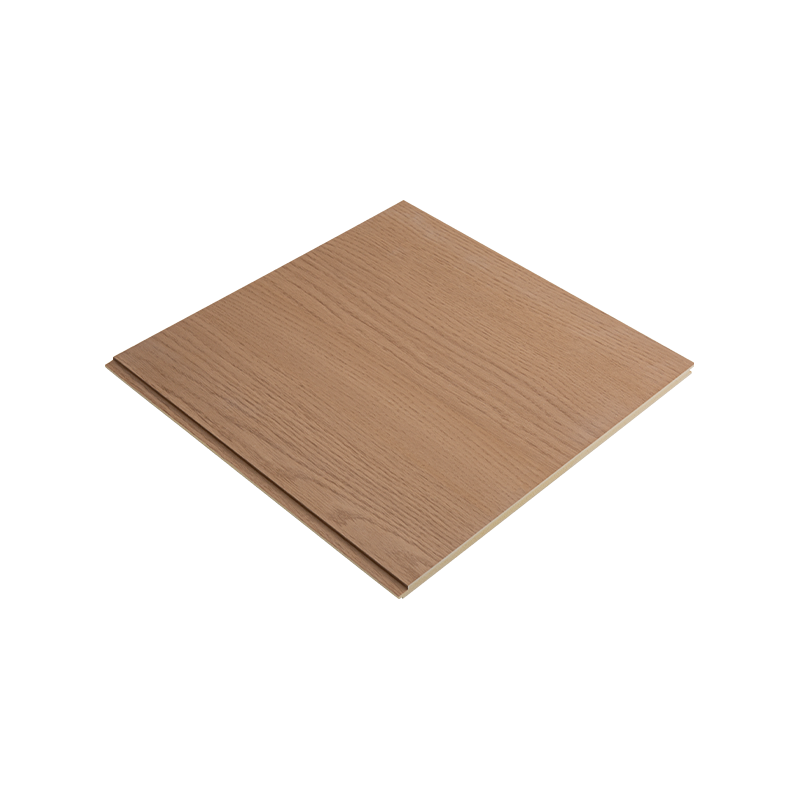

Wood Plastic Composite (WPC) hollow wall panels have emerged as a versatile solution for both interior and exterior construction projects. Combining the durability of plastics with the natural aesthetic of wood fibers, these panels offer a sustainable alternative to traditional building materials. Their hollow structure not only reduces material usage and overall weight but also improves insulation and acoustic performance. In recent years, the popularity of WPC hollow wall panels has increased significantly, driven by their ease of installation, low maintenance, and wide range of design options. Homeowners, architects, and contractors are increasingly turning to these panels for applications ranging from decorative interior walls to durable exterior cladding. High demand for waterproof WPC wall panel solutions and decorative WPC wall panel designs further reinforces their market potential.

Material Composition and Manufacturing Process

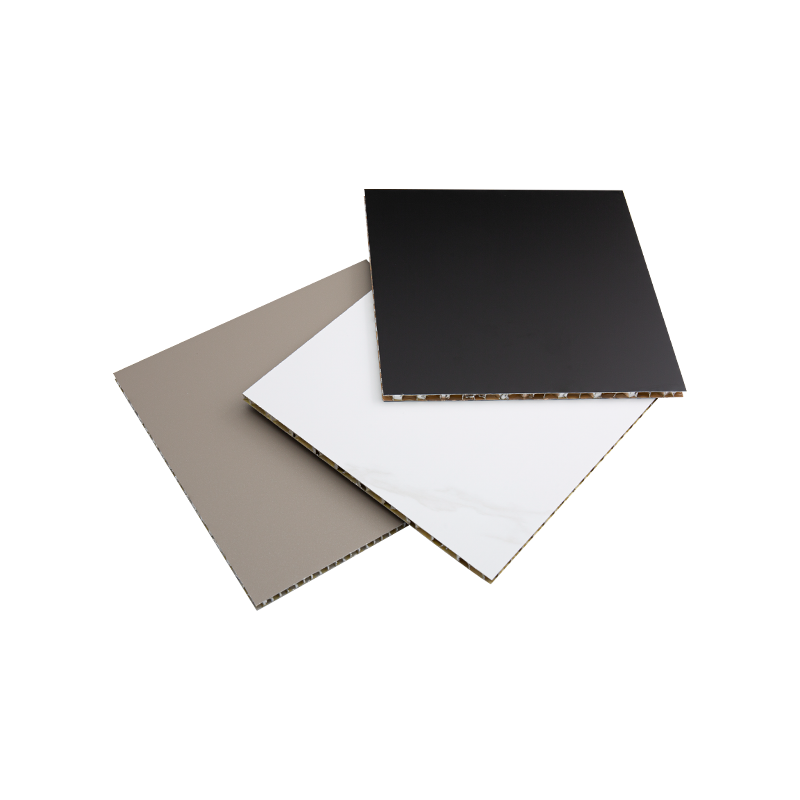

WPC hollow wall panels are made from a combination of wood fibers or bamboo powder and thermoplastic materials such as HDPE, PP, or PVC. This blend allows the panels to retain the natural appearance and texture of wood while benefiting from the water resistance, durability, and flexibility of plastics. The hollow design reduces the overall weight of the panels, making them easier to handle, transport, and install compared to solid wood or composite panels.

The manufacturing process typically involves extrusion or compression molding, followed by surface treatment to enhance aesthetics and performance. Additives such as UV stabilizers, flame retardants, and colorants are often incorporated to improve durability and safety. Surface finishes can vary from wood grain patterns to smooth or decorative textures, catering to both functional and aesthetic requirements.

WPC Hollow Wall Panel Material Composition and Features

| Component | Function | Typical Ratio | Benefits |

|---|---|---|---|

| Wood Fiber | Reinforcement | 40-60% | Provides natural texture and stiffness |

| HDPE/PP/PVC | Binder & durability | 40-60% | Water resistance and long-lasting performance |

| Additives | UV stabilizers, flame retardants | 1-5% | Improved durability and safety |

| Surface Coating | Decorative finish | 0.5-2% | Enhanced color, texture, and UV resistance |

This combination of materials and design ensures that WPC hollow wall panels deliver a balance of strength, lightweight performance, and aesthetic appeal, making them suitable for a wide range of construction and decorative applications.

Key Features and Advantages

WPC hollow wall panels offer a range of features that make them a preferred choice for modern construction and interior design. One of the primary advantages is their waterproof and moisture-resistant properties, which make them ideal for bathrooms, kitchens, and other high-humidity areas. Their lightweight hollow structure facilitates easy handling and installation, reducing labor costs and construction time.

In addition to functional benefits, these panels provide soundproofing advantages, helping to improve acoustic comfort in offices, conference rooms, and residential spaces. They are also UV resistant, maintaining their color and surface quality even when used in exterior applications exposed to direct sunlight. The decorative potential of WPC hollow wall panels is significant, with a variety of textures, colors, and patterns available, including wood grain, stone, and smooth finishes. Furthermore, the sustainable composition of WPC materials, often incorporating recycled plastics and wood fibers, makes them an environmentally responsible choice.

WPC Hollow Wall Panel Performance Comparison

| Feature | Description | Benefits | Ideal Use Case |

|---|---|---|---|

| Waterproof | Resists water and moisture | Long-lasting, low maintenance | Bathrooms, kitchens |

| Lightweight | Hollow design reduces weight | Easy transport and installation | Interior walls, partitions |

| Soundproof | Absorbs sound | Improves acoustics | Offices, conference rooms |

| UV Resistant | Protects from sun damage | Maintains color and surface | Exterior cladding, balconies |

| Decorative | Variety of textures and colors | Enhances interior/exterior | Living rooms, hotels, commercial spaces |

| Eco-friendly | Made with recycled materials | Sustainable construction | Green building projects |

These combined features make WPC hollow wall panels a versatile and efficient material for both interior and exterior applications, providing durability, aesthetics, and sustainability in a single solution.

Applications Across Industries

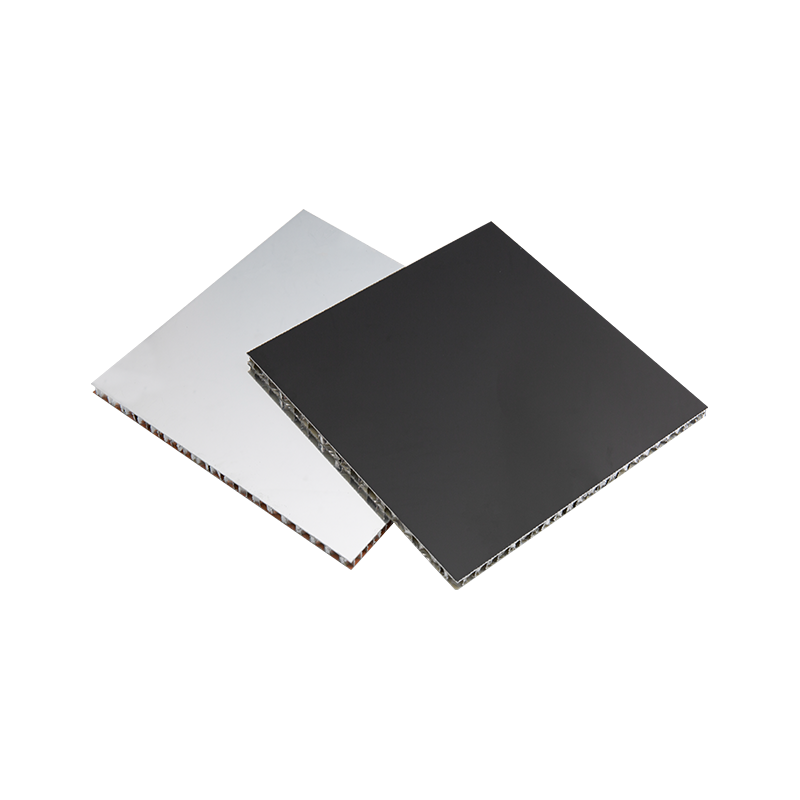

WPC hollow wall panels are highly versatile and find applications across a wide range of industries. In residential spaces, they are commonly used for interior walls, partitions, and decorative features. Their lightweight hollow design and ease of installation make them an excellent choice for living rooms, kitchens, bathrooms, and bedrooms. Many homeowners prefer these panels for interior decoration due to their waterproof and low-maintenance properties, making them a practical yet stylish solution.

In commercial and office environments, WPC interior wall paneling provides both aesthetic appeal and functional benefits, such as soundproofing and durability. Offices, conference rooms, and retail spaces benefit from the panels’ ability to improve acoustics while adding a modern, decorative look. Additionally, their lightweight nature reduces installation time, which is valuable in fast-paced commercial projects.

For exterior applications, WPC exterior wall cladding has become increasingly popular. These panels are designed to withstand outdoor conditions, including UV exposure, rain, and temperature fluctuations. They are suitable for balconies, façades, and garden structures, offering a combination of durability, decorative appeal, and environmental sustainability.

Specialized applications include soundproof partitions, temporary construction walls, and renovation projects where quick installation and minimal structural impact are essential. The eco-friendly nature of these panels also makes them a preferred choice in green building projects and sustainable construction initiatives.

Installation Guidelines and Best Practices

Proper installation is crucial to maximize the performance and longevity of WPC hollow wall panels. Before beginning, it is essential to prepare the surface by ensuring it is clean, dry, and level. Accurate measurement and planning are necessary to achieve precise panel alignment and minimize waste. The lightweight nature of the panels simplifies handling, but careful attention to alignment and joint treatment is required for a professional finish.

Installation typically involves cutting the panels to size, fixing them to the wall using screws, clips, or adhesive, and sealing joints with appropriate sealants to ensure waterproofing. Maintaining consistent spacing between panels helps accommodate thermal expansion and prevents warping over time. It is also recommended to follow manufacturer guidelines for any additional accessories or surface treatments.

Installation Tools and Materials

| Tool/Material | Purpose | Notes |

|---|---|---|

| Measuring Tape | Accurate measurement | Essential for precision |

| Saw / Cutter | Cutting panels | Use recommended blades to avoid damage |

| Screws / Clips | Fixing panels | Ensure compatibility with panel design |

| Adhesive / Sealant | Waterproof sealing | For joints and edges |

| Level / Spacer | Alignment | Ensures flat and even surface |

By following best practices, installers can ensure that WPC wall panels maintain their structural integrity, aesthetic appeal, and functional properties such as waterproofing and soundproofing. Careful installation not only enhances the panels’ appearance but also contributes to their long-term durability and performance.

Maintenance and Longevity

WPC hollow wall panels are designed for durability, but proper maintenance is essential to ensure long-term performance. Regular cleaning with a soft cloth or sponge and mild detergent helps prevent the buildup of dust, dirt, and stains. Avoid abrasive cleaners or harsh chemicals, as these can damage the surface finish and reduce the panels’ decorative appeal.

Periodic inspection of joints, fasteners, and edges is recommended to detect any signs of wear, warping, or water ingress. In areas exposed to direct sunlight or outdoor conditions, applying a protective coating or UV stabilizer can help preserve color and surface integrity. For soundproof or decorative panels, maintaining a clean surface also contributes to optimal acoustic and aesthetic performance.

By adhering to simple maintenance practices, homeowners and contractors can significantly extend the lifespan of WPC hollow wall panels, ensuring they continue to deliver waterproofing, durability, and decorative appeal for many years. This makes them a reliable and cost-effective choice for both interior and exterior applications, reinforcing their growing popularity in modern construction and renovation projects.

Challenges and Solutions

Despite their many advantages, WPC hollow wall panels can face certain challenges during installation and use. One common issue is improper installation, which may lead to misaligned panels, uneven surfaces, or gaps that compromise waterproofing and soundproofing properties. To address this, it is essential to follow precise measurement and alignment procedures, use recommended tools and fasteners, and apply sealants to protect joints and edges.

Material cost fluctuations can also affect project budgets. WPC panels rely on a combination of wood fibers and plastics, and variations in raw material prices can influence overall costs. Planning and procurement strategies, such as bulk purchasing or sourcing from stable suppliers, can help mitigate financial impact.

Environmental factors such as UV exposure, extreme temperatures, and high humidity may also affect performance over time. Selecting panels with UV resistant coatings, proper ventilation, and protective treatments ensures that panels maintain their color, texture, and structural integrity. Regular inspections and maintenance further enhance longevity, addressing potential issues before they escalate.

By understanding these challenges and implementing appropriate solutions, builders, designers, and homeowners can fully leverage the advantages of WPC hollow wall panels. Correct installation, careful material selection, and proactive maintenance not only prevent common problems but also ensure the panels continue to deliver waterproofing, soundproofing, and decorative benefits throughout their lifespan.

Conclusion

WPC hollow wall panels offer a unique combination of durability, aesthetic appeal, and environmental sustainability. Their hollow design provides lightweight handling and insulation benefits, while the use of recycled wood fibers and plastics supports eco-friendly construction practices. Whether used for interior wall paneling, exterior cladding, or specialized applications such as soundproof partitions, these panels provide versatile solutions that meet both functional and decorative needs.

FAQ

FAQ 1: What is a WPC hollow wall panel?

A WPC hollow wall panel is a building material made from wood fibers or bamboo powder combined with thermoplastic materials. Its hollow design reduces weight while providing durability, insulation, and decorative options.

FAQ 2: How do I choose between interior and exterior WPC wall panels?

Interior panels are typically selected for decorative and moisture-resistant properties, while exterior panels should offer UV resistance, weather durability, and waterproofing for long-term outdoor performance.

FAQ 3: How should WPC hollow wall panels be maintained?

Regular cleaning with mild detergents, periodic inspection of joints and fasteners, and protective coatings for UV exposure help maintain the panels’ appearance and performance.

FAQ 4: Is installation of WPC hollow wall panels difficult?

Installation is straightforward with proper tools, accurate measurements, and adherence to manufacturer guidelines. Lightweight panels simplify handling and reduce labor requirements.

FAQ 5: Are WPC hollow wall panels environmentally friendly?

Yes, many WPC panels use recycled wood fibers and plastics, making them a sustainable choice for green building projects while reducing the environmental impact of traditional materials.

English

English عربى

عربى русский

русский